Application examples:

- cleaning and degreasing of workbenches, walls and ceilings

- cleaning and defrosting refrigeration fins and coils

- chemical free killing of listeria in drains and pipes

- cleaning and maintenance of ventilation ducts

- removing food residues

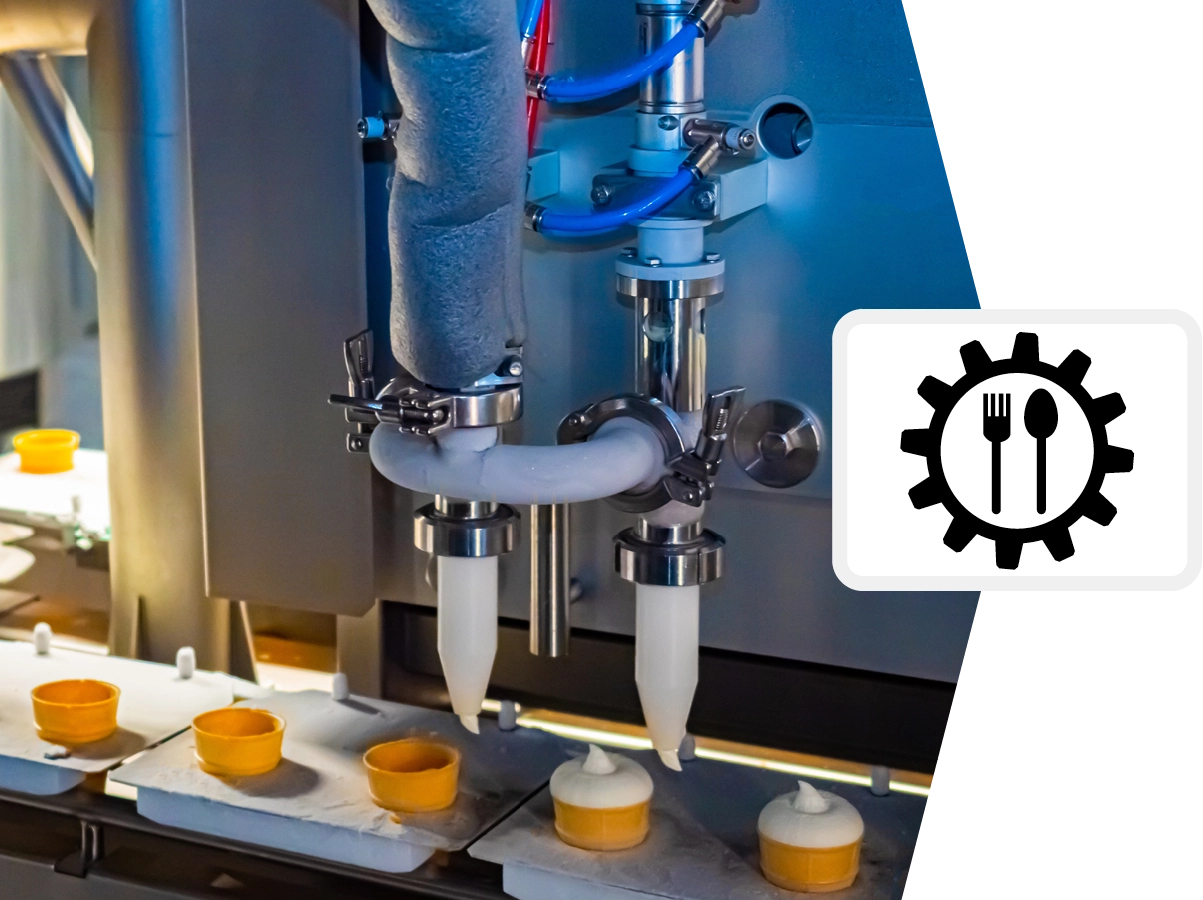

- cleaning of batching systems

- cleaning and sanitizing of blending tanks

- removing grease from control panelsand electrical boards

- sanitizing filters and grilles

- thorough cleaning of conveyors, chains, belts, rollers and packings

- sanitizing of refrigeration systems without removing food

Food processing sanitation is a key element in protecting the public from germs, pathogensand harmful bacteria that can lead to serious illness. The food industry uses strong cleaning and sanitizing lines and programs to eliminate each kind of bacteria and virus. Traditional sanitizing is a two-stage process: first, the initial cleaning with water and detergents; second, disinfecting with the aid of harsh chemicals such as chlorine, iodine, quaternary ammonium salts, acid and formaldehyde-based substances. Adopting an effective cleaning and sanitizing program is crucial to eliminating pathogens from surfaces and equipment. With Menikini industrial steam machines this type of processing becomes faster and easier as dry steam reduces system and line down times and saves chemical costs. Menikini machines also guarantee total sanitizing and killing of microorganisms because of the heating shock.

Fields marked with * are required.

Fight risks of food safety hazards

Hazard analysis and critical control points, or HACCP, is a systematic preventive approach to food safety and pharmaceutical safety that addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection. It involves monitoring, verifying and validating of the daily work that is compliant with regulatory requirements in all stages all the time. HACCP is used in the food industry to identify potential food safety hazards, so that key actions can be taken to reduce or eliminate the risk of the hazards being realized. The system is used at all stages of food production and preparation processes including packaging, distribution, etc. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) say that their mandatory HACCP programs for juice and meat are an effective approach to food safety and protecting public health. The use of HACCP is currently voluntary in other food industries. Hence, HACCP has been increasingly applied to other industries, such as cosmetics and pharmaceuticals. This method, which in effect seeks to plan out unsafe practices, differs from traditional "produce and test" quality control methods which are less successful and inappropriate for highly perishable foods.

HACCP application range

Fish and fishery products

Fresh-cut produce

Juice and nectar products

Food outlets

Meat and poultry

products

School food and services

The development, implementation, and certification of an HACCP system, besides enhancing the efficiency of the production plant resulting from the minimization of production rejects and returns, also enables the manufacturing companies to offer a completely guaranteed product quality to their customers. The Menikini machines, put to the test to evaluate the effectiveness of steam in damping fungi and bacteria, have been proved to be more and more effective, amply within the parameters specified by the European standards related to chemical and antiseptic disinfectants. For all cleansing and sanitizing activities hereunder reported, traditional systems may be replaced with the use of saturated dry steam with advantages regarding water, detergent and disinfectant consumption. Usually where meals are prepared and administrated the following equipment is present:

refrigerators

and cold stores

rapid temperature decreaser

thermal convection ovens

microwave ovens

deep-fryers

braziers

water-boilers

pasta-cooker

dish-washers

slicing-machines

mincing-machines

citrus-fruit squeezers

mixers

emulsifiers

drinks distributors

ice-cream dispensers

ranges and heating plates

GENERAL VAPEUR S.r.l.

Registro delle Imprese di Milano al n. 01166520997 • Capitale sociale i.v. € 1.800.000,00 • R.E.A. MI-1912252

PEC generalvapeur@pec.it

© Copyright 2020 Menikini